Redgarden Engineering offers a high level of electronic design capability that clients may utilize exactly when needed. We enjoy innovating, solving problems, and organizing complex pieces in useful, clear ways, and we can provide continuing support for our designs over periods of many years.

Redgarden Engineering uses a multi-disciplinary team for most electronics design projects. We have found that such a team is usually better, faster, and much more cost-effective than a single engineer. Depending on your project, your Redgarden team may include an electronics design engineer, an electronics checking engineer, a printed circuit board layout technician, an electronics manufacturing engineer, an assembly technician, a purchasing agent, and sometimes a software or a mechanical engineer.

Design Services: Electronic & Software Design • Printed Circuit Board Layout • Mechanical Design

Project Management

Design Review Services

Other Services: Technical Writing and Patent Analysis • Parts Kitting, & Assembly •

Electronics Product Tear-down & Analysis • Training & Expert Testimony

Electronic & Software Design Services

We draw our ideas both from past experiences as well as from new materials and your suggestions. This helps us to to provide you with elegant, robust designs within the constraints of your budget and schedule.

We can meet at your facility during critical phases so that we design exactly what is needed.

Analog Circuits:

Pre-amps, filters, etc.Controls:

Analog & digital controlsOpto-Electronics:

Photodiodes, laser diodes, etc.Power Electronics:

DC-DC switching power supplies, power amplifiers, etc.Digital Circuits:

Microprocessors, USB, Ethernet, etc.Logic Designs:

Verilog or VHDL code & simulation for FPGAs & CPLDsEmbedded & Computer Software:

C & C++; C#; Linux, SQL, PHP, etc.We can use Orcad and Altium for schematic capture.

Printed Circuit Board (PCB) Layout

An infinite number of ways exist to convert your circuit design into a printed circuit board. Let Redgarden Engineering’s expertise handle this critical part of your design!

Critical initial design and design changes can be quickly and efficiently implemented at your facility to save you time and expense. This facilitates communications and helps to avoid costly PCB design iterations.

- PCB layout review by a Manufacturing Engineer

- Low noise designs

- Controlled impedance and high-current traces

- High voltage creepage & clearance

- Minimized/controlled loops for DC-DC switchers

- Optimum board material, thickness, and layer stackup

We use Pads, Altium, and Orcad/Allegro for PCB layouts.

PCB Layout by Redgarden Engineering

Mechanical Design

Many of the mechanical designs that Redgarden does are in support of other aspects of an instrument or product. On many occasions, we have modeled and designed enclosures and three-dimensional outlines for printed circuit boards. However, our capabilities are much broader than this. We can also provide thermal analysis and other mechanical engineering upon request. Most of our mechanical designs are in SolidWorks.

Project Management

For complex projects, we can assemble and manage a team of electrical, mechanical, software, and manufacturing engineers along with related support including electronics assemblers and technicians. Engineering can be provided on a best-effort, hourly rate (the usual method) or as a fixed-bid (with good project definition and understanding; usually a 30% mark-up). We provide the client with a single project invoice separately describing the work of each contributor.

Our services span the typical formal project phases (research, planning, design input & output, verification & validation, transition to manufacturing, and sustaining). Less formally, most projects include the following elements:

- Communicate. Keep clear communication channels (through email, telephone, and face-face meetings) with the client, vendors, affiliates, and other engineers working on the project.

- Gather requirements. Write a specification. Create a budget and a list of milestones. Review & iterate as necessary.

- Research & explore. Simulate or prototype critical items.

- Do the engineering design. Review with the customer.

- Build, troubleshoot, and modify the design as needed. Test against the specification. Document the design.

- Support the users. Wrap up the project and acknowledge team members. Appreciate what was achieved overall.

- Manufacturing phase-in. Provide support as needed to move the design into production. Identify and audit vendors, get volume pricing, write manfuacturing work instructions, etc.

Design Review Services

We are happy to provide review services for others’ designs. These can include detailed reviews by our individual engineers as well as attending on-site review meetings. Review topics may include:

- Requirements and Specifications

- Electronics Design (including schematics, bills of materials, layout notes, Spice & logic simulations, calculations, etc.)

- Software and Logic Design (including design strategy, algorithms, high level code organization, and/or details of code)

- Printed Circuit Board Layout (including parts placement, routing, footprints, paste mask, Gerbers, panelization strategy, etc.)

- Mechanical Design (including drawings, 3-D models, calculations, etc.)

- Test, Verification, & Validation Plans and Results

Technical Writing & Patent Analysis by Engineers Who Can Write

- Requirements, specifications

- Risk management, failure modes effects analysis, etc.

- Research protocols; verification & validation protocols

- Technical manuals & websites (e.g., this website)

- Grants

- Assistance with patent writing and analysis

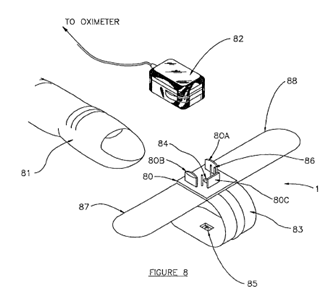

U.S. Patent 5,851,178, Pulse Oximeter Probe Connector with Laser Diodes

Parts Kitting & Assembly

We can buy and kit parts from either a bill of materials (BOM) that we generate or from a BOM that you have. We can follow that up by having our electronics assemblers hand-stuff PCBs (as practical) as well as coordinating with a printed circuit board fabrication house and an automated circuit board assembly house.

We have found that it is often quickest and cheapest to hand-assemble the first few printed circuit board assemblies for a prototype job. However, parts with ball grid arrays (BGAs) and quad flat no-lead packages (QFNs) with multiple pads on the bottom generally require machine stuffing.

An electronics technican can build and test cables and cable harnesses, chasses, etc.

Electronics Product Tear-down & Analysis

We can open up an electronics product to analyze how it appears to function and how it is put together. This can be useful for both competitive product analysis and for assessing apparent likelihood of possible patent infringement. (Note that we can't say that a product is actually infringing—this is a matter for patent attorneys and the courts.)

Training & Expert Testimony

On-Site training is available for engineers, technicians, scientists, and others on such topics as:

- Electronic Design

- PCB Layout

- Electronics Troubleshooting

- Signal integrity & designing to minimize electro-magnetic compatibility (EMC/EMI) issues

- Spice Simulation

- Drawing clear, concise electronics schematics

- Writing clear, concise programmable logic code

Expert testimony are offered, particularly in areas of experience.